Tool shop

Our in-house tool shop for optimal solutions

The manufacture of precision deep-drawn parts is a job for experienced specialists – and the same applies to the tools required to produce them to the highest standards and without deviations. That is why we have relied on in-house tool shop almost since the beginning of our company’s 100-year history.

The tools used in our plants in Germany, the Czech Republic, China, and the USA are one of the most important instruments for ensuring the uncompromising quality of our deep-drawn parts. At our headquarters in Bielefeld, a team of 25 experienced toolmakers and machinists work in rotating shifts to ensure that our machines in the affiliated production areas run optimally at all times – and that new projects can be implemented not only quickly, but also at the highest level.

Adjacent interfaces to our design department, the assembly area, and our Global Research & Development Center help ensure that our toolmaking team can react flexibly and quickly at all times.

Highly complex and strategically essential design components are manufactured exclusively in-house – this ensures that our technical know-how, which has been developed and perfected over decades, remains within the company and promotes and continuously increases our innovative strength and productivity.

Do you have an idea?

We find a solution. Together.

Frank Laufen

Head of Tool Shop

Innovative processes

Made in Germany

Experts

Know-how meets innovation

Our modern machining departments bring together what can be described as the formula for success in toolmaking: innovative technology and the high level of expertise of our experienced employees.

Highly specialized knowledge has been passed down through generations at our company – this benefits new customers and all new projects in particular, where the aim is to develop customized solutions in a short period of time. The toolmaking experts are involved in every process right from the design phase – the “hand-in-hand” principle and independence from external suppliers ensure that we can set our own standards in terms of quality and process speed.

Specialists for a wide range of materials and processes

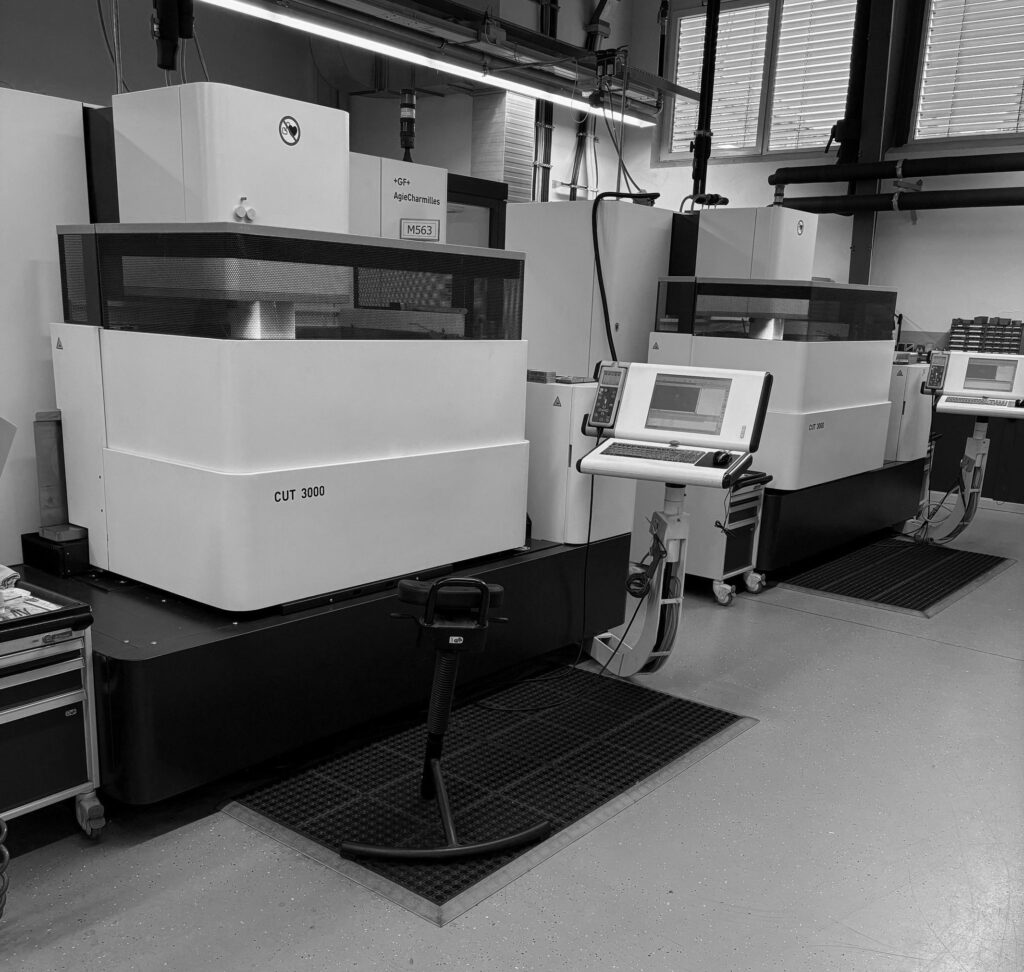

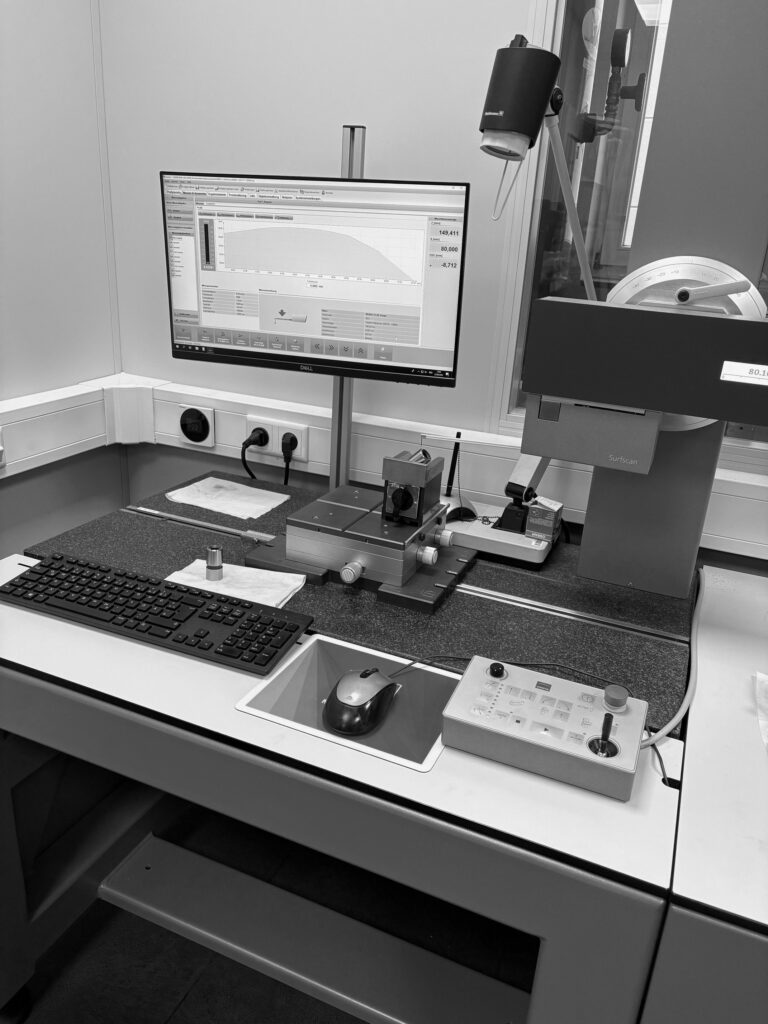

Whether carbide, ceramic, or PM steel, whether turning, milling, surface grinding, external and internal cylindrical grinding, radius and contour grinding of drawing dies, sinker or wire EDM, or hard machining of complex components of all kinds: Our dedicated team has in-depth expertise in all areas of metal forming and toolmaking, which are of utmost importance for the production of our deep-drawn parts. Equipped with a measuring laboratory and air-conditioned areas for precision machining, where every last µ counts, our customers can always rely on results of the highest quality.

Two modern hardening furnaces are available for internal heat treatment for immediate requirements, which significantly reduces production time.

We are also supported by external service providers and long-standing partners in the immediate vicinity. When it comes to heat and surface treatment of our components, we can also draw on a wide range of coating options and types of tempering.

Toolmaking “Made in Germany”

Thanks to a high degree of standardization in our procurement processes, our own service center, and comprehensive spare parts management, our toolmaking department is always able to respond quickly and flexibly to new situations – on a global scale. Our locations in China, the Czech Republic, and the USA also benefit from our “Made in Germany” toolmaking, of course.

Thanks to our raw material and semi-finished product warehouse for our high-runners and special components, all relevant materials are in stock to avoid procurement bottlenecks.

In addition, our in-house tool shop is already highly digitized – an industry-specific project management system enables us to view processes transparently and consistently, mapping everything from inquiries to resource and capacity planning to internal order billing – everything that is necessary for project-based manufacturing.

This is fully in line with our future-oriented strategy of complete digitization of our processes, in which the aspects of sustainability, efficiency, document security, and cost reduction are of utmost importance.

Euscher GmbH & Co. KG

Plant I

Johanneswerkstrasse 22

33611 Bielefeld

Germany

+49 521 80009 - 0

Euscher GmbH & Co. KG

Plant II

Vilsendorfer Strasse

33611 Bielefeld

Germany

+49 521 80009 - 0

Euscher Precision Deep Drawing (Anhui) Co., Ltd.

No.5, Technology Road, Chahe Economic Development Zone

239236, Lai'an, Chuzhou City, Anhui Province

PR China

+86 18512521659