Tool design

Tool design – this is where precision begins

The tool design department at our headquarters in Bielefeld is the heart of technical implementation – this is where ideas for new thermoformed parts are turned into functional solutions.

Under the leadership of Eduard Rac, the team develops high-quality forming tools using their many years of experience, technical expertise, and state-of-the-art CAD and simulation software. Demanding customers from the automotive, aerosol, cosmetics, and electrical industries receive comprehensive support from the initial idea to production-ready design—efficiently, innovatively, and in partnership.

“I believe in a tool design that not only offers solutions, but also shapes the future – through bold ideas, creative approaches, and precise mastery of thermoforming technology.”

Eduard Rac, Head of Tool Design

Do you have an idea?

We find a solution. Together.

Eduard Rac

Head of Tool Design

Innovative processes

Made in Germany

Experts

Innovation begins before design

For the technical office, successful design begins even before the first CAD model is created. Working closely with international customers, the team analyzes all requirements, develops initial approaches, and—if desired—simulates the future product even during the pre-development phase. In this way, the Euscher tool design department creates a solid foundation for future tool design at an early stage and also ensures short development times and high process reliability.

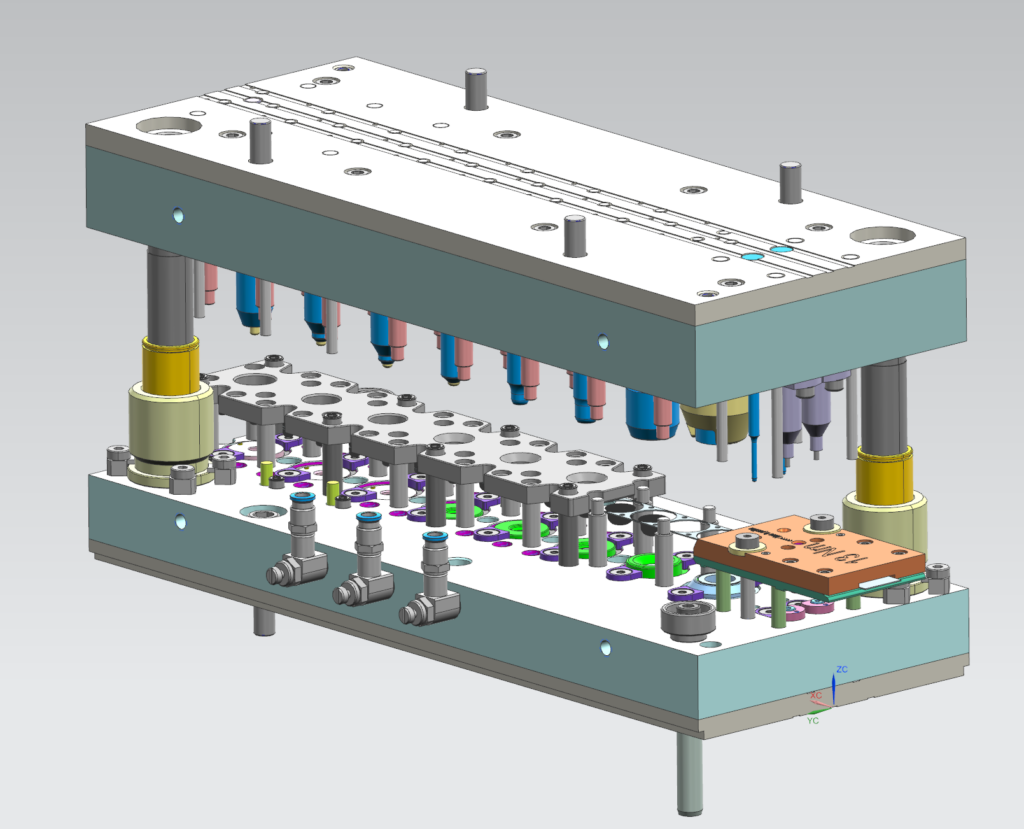

Digital tool design using state-of-the-art technology

The team led by Eduard Rac uses powerful CAD software to precisely design complex forming tools. All designs are well thought out, functional, and tailored for smooth implementation in production. Working closely with the in-house tool shop department and production at all Euscher Group locations, our design department ensures that every detail fits—both virtually and in reality.

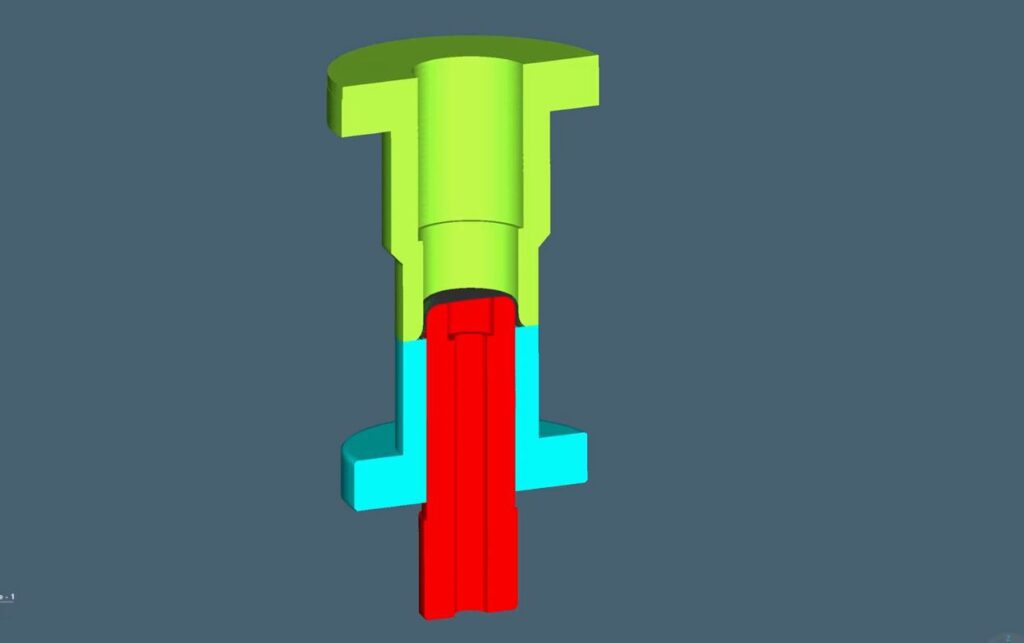

Simulation and optimization of forming processes

By simulating deep-drawn parts before the actual design phase, forming processes can be analyzed precisely and potential challenges identified at an early stage, allowing the process to be adapted or further developed accordingly. In addition, the team of experts is able to create its own flow curves for the simulation, enabling even more precise adaptation to specific requirements.

This flexibility allows us to act quickly while ensuring that the tools and products are robust, economical, and reliable under real-world conditions.

Euscher GmbH & Co. KG

Plant I

Johanneswerkstrasse 22

33611 Bielefeld

Germany

+49 521 80009 - 0

Euscher GmbH & Co. KG

Plant II

Vilsendorfer Strasse

33611 Bielefeld

Germany

+49 521 80009 - 0

Euscher Precision Deep Drawing (Anhui) Co., Ltd.

No.5, Technology Road, Chahe Economic Development Zone

239236, Lai'an, Chuzhou City, Anhui Province

PR China

+86 18512521659