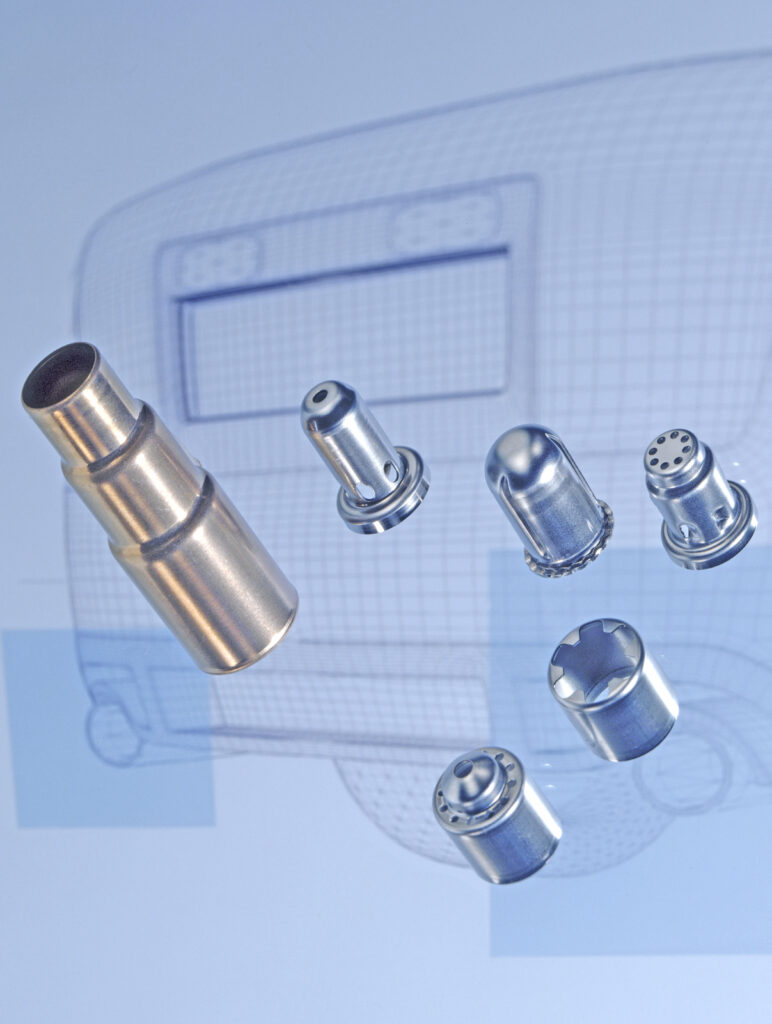

Deep-drawn parts for the automotive industry

Sector solutions for the automotive industry

Precision deep-drawn metal parts play a crucial role in the automotive industry. The highly specialised components offer a number of advantages that make them indispensable for use in vehicles of all types and drive systems. At Euscher GmbH & Co. KG, we have been dedicated to the production of customised, high-quality components for the automotive industry (e.g. sensor sleeves for exhaust sensors/lambda probes, shock absorbers, temperature sensors, lubrication, oil pressure valves, camshaft adjustment, brakes, steering, gearboxes, water pumps, shields, connectors and high-voltage connections) since the 1970s. Based on our many years of experience, our thermoforming experts are able to create highly complex geometries and quickly go into mass production.

Precision deep-drawn parts offer numerous advantages for the automotive industry, from weight reduction and cost savings to improved performance characteristics. Their versatility, precision and durability make them a key component in modern vehicle manufacturing, helping to continually push the boundaries of innovation and design.

Do you have an idea?

We find a solution. Together.

Jarid Asseburg

Key Account Management

Use of deep-drawn parts in the automotive industry – the advantages

Precision and quality

Our high-quality precision deep-drawn parts made from sustainable materials are manufactured with the highest precision, which is of the utmost importance for the automotive industry, where every component must fit exactly. Our parts fulfil even the strictest tolerance requirements, resulting in improved performance and longevity of the vehicles and their installed technology.

Versatility

Precision deep-drawn metal parts can be produced in a variety of shapes, sizes and materials to meet the specific requirements of automotive manufacturers. Whether complex geometric shapes or parts that require special mechanical properties, thermoforming technology offers the necessary flexibility.

Weight reduction

At a time when reducing vehicle weight to increase efficiency and reduce emissions is becoming increasingly important, precision deep-drawn parts offer an effective solution. They enable the production of lightweight yet robust components that contribute to the overall efficiency of the vehicle.

Cost savings

By utilising advanced manufacturing technologies and the ability to produce parts with minimal material waste, precision deep-drawn parts can lead to significant cost savings in production. The efficiency of the thermoforming process also reduces the need for subsequent processing steps, which leads to further savings.

Durability and resilience

Precision deep-drawn metal parts are characterised by their exceptional durability and resistance to environmental influences such as corrosion and extreme temperatures. These properties are invaluable for vehicle components that have to function under harsh conditions.

Aesthetics and functionality

In addition to the technical advantages, precision deep-drawn parts also improve the aesthetics of vehicle components. Manufacturing technology supports the production of parts with smooth surfaces and precise contours that can improve both the visual appearance and aerodynamic efficiency of vehicles.

Automotive – a head start with deep drawing technology

We are the visionary deep-drawers with decades of experience as an automotive supplier: talk to us and we will show you what is possible with this technology. Our design engineers know exactly how far you can go with the various materials, our tools from our own tool shop and modern machines.

Where downstream machining is required elsewhere, we produce highly complex geometries for the individual requirements of our customers in the automotive industry in just one process. And for complex turned or cast parts, we can provide you with cost-effective alternatives and quickly produce to mass.

You can always rely on our special deep-drawing expertise. According to your wishes, we realise deep-drawn parts from a wide variety of materials in the most diverse geometries and the most varied quantities required. To achieve the best results, we always push materials, tools and machines to the limits of what is possible. This means you benefit from customised deep-drawn parts of the highest precision and quality that precisely match your requirements.

Innovative products and processes for the automotive industry

When it comes to precision deep-drawn metal parts and assemblies, Euscher has exceptional expertise. We have been proving our innovative strength and experience time and again for 100 years. We are also happy to develop individual products for you – or bring your specifications to series production in a structured manner.

Every large-scale production run is optimally tailored to your requirements. To achieve this, the Euscher team sometimes takes an unconventional technological approach: we can even produce highly complex geometries at high working speeds.

Creating new things together

As an experienced automotive supplier, we are also happy to support you with your new developments. We are curious about your visions: Take advantage of our many years of experience in the industry at an early stage so that we can realise your ideas together! We work in partnership with you to develop the optimum solution – a cost-effective product of the highest quality that is ideally suited to the desired application.

You can expect a service that is reliably and specifically tailored to your requirements. We are happy to explore the limits of what is possible and, where possible, we will exceed them for you. To achieve this, we work hand in hand internally: In an integrated development process, our teams from sales, design, toolmaking, production and quality assurance get your innovations off the ground.