Deep-drawn parts for the electronics industry

Sector solutions for the electrical industry

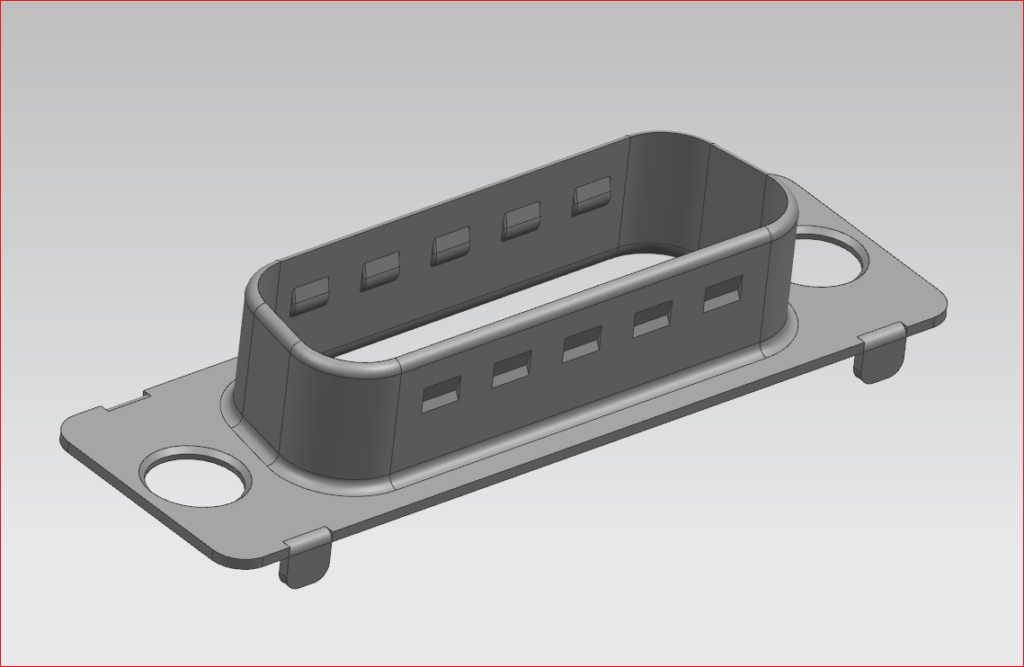

Whether sensor housings, Sub-D connectors, VGA connectors, sensor sleeves, high-voltage connectors or DIN connectors – high-quality precision deep-drawn metal parts are an innovative solution for the electronics industry, electrical engineering and e-mobility. The electrical industry is constantly faced with the challenge of developing powerful and reliable components that meet the increasing demands of technology. One key technology that plays a decisive role in the manufacture of high-precision components such as SUB-D connectors, VGA connectors and DIN connectors is deep-drawing technology. This process makes it possible to manufacture metal parts with very high precision, which is crucial for the quality and functionality of the end products.

At Euscher, we are your deep-drawing experts with years of experience as suppliers to manufacturers in the electronics and electrical engineering sectors. We produce high-quality and sustainable precision deep-drawn parts in bulk to meet your individual requirements.

Do you have an idea?

We find a solution. Together.

Jarid Asseburg

Key Account Management

Deep-drawn parts in the electrical and electronics industry – the advantages

Sustainability

The efficiency of the thermoforming process leads to a reduction in material consumption and the energy required for production. The metals used in thermoforming technology are fully recyclable, which further minimises the environmental impact. These aspects contribute to the sustainability of the production processes.

Cost efficiency

Deep drawing enables high production efficiency, as parts can be produced in large quantities with minimal material waste. This leads to a significant reduction in production costs. In addition, the deep-drawing process requires less post-processing compared to other manufacturing processes, which also saves time and money.

Versatility

Thermoforming technology offers exceptional design freedom, allowing manufacturers to develop components that are customised to the specific requirements of their applications. This flexibility is particularly important in the electrical industry, where component requirements are constantly changing and evolving.

Precision and quality

The production of components for SUB-D connectors, VGA connectors and DIN connectors requires extremely precise dimensional tolerances to ensure reliable functionality and compatibility. Deep-drawing technology enables manufacturers to achieve the required precision and thus optimise the quality and reliability of electronic connections.

Electronics industry – a head start with deep-drawing technology

Deep-drawn parts offer the electrical industry and companies that manufacture electronic products a range of benefits, from design flexibility to durability, quality and sustainability. Our technology enables manufacturers to develop innovative, attractive and functional components that not only fulfil today’s requirements, but even exceed them.

Benefit from Euscher’s expertise, because we produce complex geometries for the individual requirements of the electronics industry and e-mobility in just one process and realise precisely fitting deep-drawn parts in a wide range of geometries and required quantities from the various materials.

Innovative products and processes for the electrical industry

When it comes to precision deep-drawn metal parts and assemblies, Euscher has exceptional expertise. We have been proving our innovative strength and experience time and again for 100 years. We are also happy to develop individual products for you – or bring your specifications to series production in a structured manner.

Every large-scale production run is optimally tailored to your requirements. To achieve this, the Euscher team sometimes takes an unconventional technological approach: we can even produce highly complex geometries at high working speeds.

Creating new things together

As an experienced supplier to the electrical and electronics industry, we are also happy to support you with your new developments. We are curious about your visions: Take advantage of our many years of experience in the industry at an early stage so that we can realise your ideas together! We work in partnership with you to develop the optimum solution – a cost-effective product of the highest quality that is ideally suited to the desired application.

You can expect a service that is reliably and specifically tailored to your requirements. We are happy to explore the limits of what is possible and, where possible, we will exceed them for you.

To achieve this, we work hand in hand internally: In an integrated development process, our teams from sales, design, toolmaking, production and quality assurance get your innovations off the ground.